Professional 3D Printing solution for dental

ORIGINAL PRUSA MEDICAL ONE

How does it work?

- The dentist uses a special 3D scanner to create a digital model of the client’s teeth and gums.

- The laboratory iassistant will then use it to model custom dental prostheses, models for the production of braces, drilling jigs, etc.

- Compared to conventional methods, this process is much more pleasant and accurate, especially for the patient.

Applications

- Dental Models

Our ultra-fast 3D printer delivers a high production of detailed and precise dental models for the purpose of patient education, thermoforming of aligners, or removable dies.

- Crown and Bridges

Equipping Medical One in your office you can easily manufacture aesthetic temporary crowns and bridges for your patients. Certified materials are durable enough and are available in many shades like A1, A2, A3, A3.5, B1, B2, or bleach.

- Surgical Guides

Medical One is certified for manufacturing surgical guides. Those are made from biocompatible materials which withstand sterilization in an autoclave. Thanks to their mechanical properties they are ready for effortless inserting of drill sleeves.

Certified for biocompatible resins

In cooperation with Pro3dure, a German manufacturer of dental resins, we have co-developed and certified workflows for several dental applications requiring biocompatibility. This process ensures that biocompatible materials are processed correctly and will not cause harm to your patients.

Our system is also open to 3rd party materials. You can freely work with any other brands available on the market and discover the full potential of digital dentistry with applications casting, gingiva masks, educational models, etc.

Maximum reliability and performance

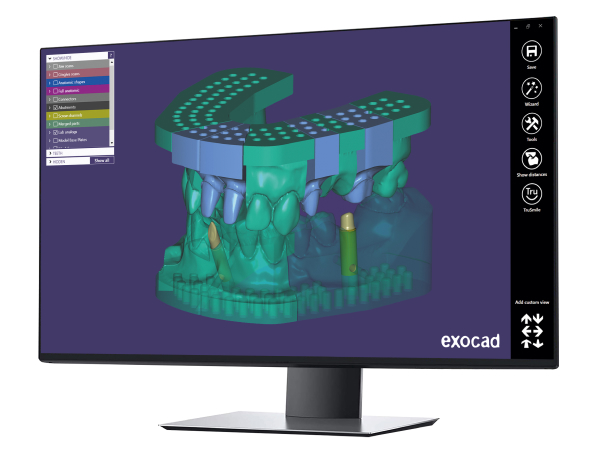

Software integration – Exocad

Medical One is now part of Exocad – an industry-leading CAD software for digital dentistry. You can simply select the printer in Model Creator or Guide Creator together with compatible material. Then the software will use tested parameters and tolerances so you can easily have the perfect fit for the model dies or for surgical guides sleeves.

To simplify the customers’ workflow, we have also integrated Exoprint into our slicing software. This results in a one-click data transfer from DentalDB to PrusaSlicer Medical that respects the material selection and orientation of the parts.

Specifications

Original Prusa Medical One

SLA 3D PRINTER

- Supported materials

- UV-sensitive resin (405 nm), third-party resins supported

- Layer Exposure Time

- 2 seconds per layer (depends on resin)

- Print area size (XYZ)

- 127×80×150 mm

- LCD display

- Monochromatic 5.96“ LCD, 2560×1620 px

- Resolution (XY)

- 0.05mm

- Layer height

- from 0.01 mm (recommended 0.05 mm)

- Connectivity

- USB, Wi-Fi, LAN, Web Interface

- Package

- Provided with resin and all accessories

- Features

-

- Automatic resin level measurement

- One-click-print

- Vapor extraction with activated carbon filter

- Safety functions

-

- Cover sensor

- Temperature measurement

- Continuous monitoring of device status

Original Prusa Medical CW One

Post-processing unit

- Purpose

- All-in-one solution for post-processing of resin-based models

- Features

-

- Resin preheat function

- Thorough washing

- Efficient drying

- 360° UV light curing

- Package

- All necessary accessories included

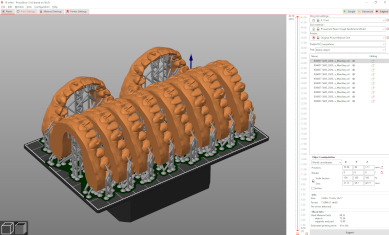

Dental Model in 5 minutes

The main feature of the Original Prusa Medical One is high performance. Especially orthodontists will appreciate the possibility of effective use of the entire printing platform.

A representative example shows 10 models designed for the production of aligners using thermoforming. The printing time of all models is only 42 minutes with printing with our Prusament Resin Model with 0.1mm layers.

Prusament Resin Model

We have developed our own materials suitable for dental models – Prusament Resin Model. Its visual and mechanical features were created as a result of extensive consultations with top industry experts. It is a very dimensionally stable material with low shrinkage and odor, and it does not cause eye fatigue because of its color. Those can also withstand the temperature of the thermoforming process, making them an ideal choice for orthodontic models.

The chosen color shades make even the most elaborate details sharp and perfectly visible. This material is also suitable for dental model prints for thermoforming bracelets. Together with your printer, you get one 0.5 kg bottle of Prusament Resin Model Solid Grey for testing. To order those resins, please contact our partners.

Precision platform

Precision printing platforms are an important part of our Medical One 3D printer. They are manufactured with maximum precision so that they can be freely exchanged without the need to calibrate the printer. This results in a significant reduction of the downtime between prints and even higher efficiency of the entire printing process.

One Precision platform is included in the Medical One printer package. If you would like to purchase more, please contact your distributor.

Integrated Management System Policy

Prusa Research a.s. is committed to the continual improvement of its integrated management system in the areas of quality, environmental protection, and occupational health and safety. Our policy is grounded in our core values, mission, and strategic direction, and is an integral part of the organization’s daily operations.

You can find more information in this document: Integrated Management System Policy (PDF)

Contact us

Partners

Our certified partners are established and customer-oriented professionals with extensive experience selling medical devices for dental surgery and labs.

A fully trained partner can provide first-class support and fast response time together with a deep knowledge of the whole workflow from scanning, over 3D printing, and finally postprocessing the part and implementing it to the patient. We teamed up with the following distributors: